What we offer

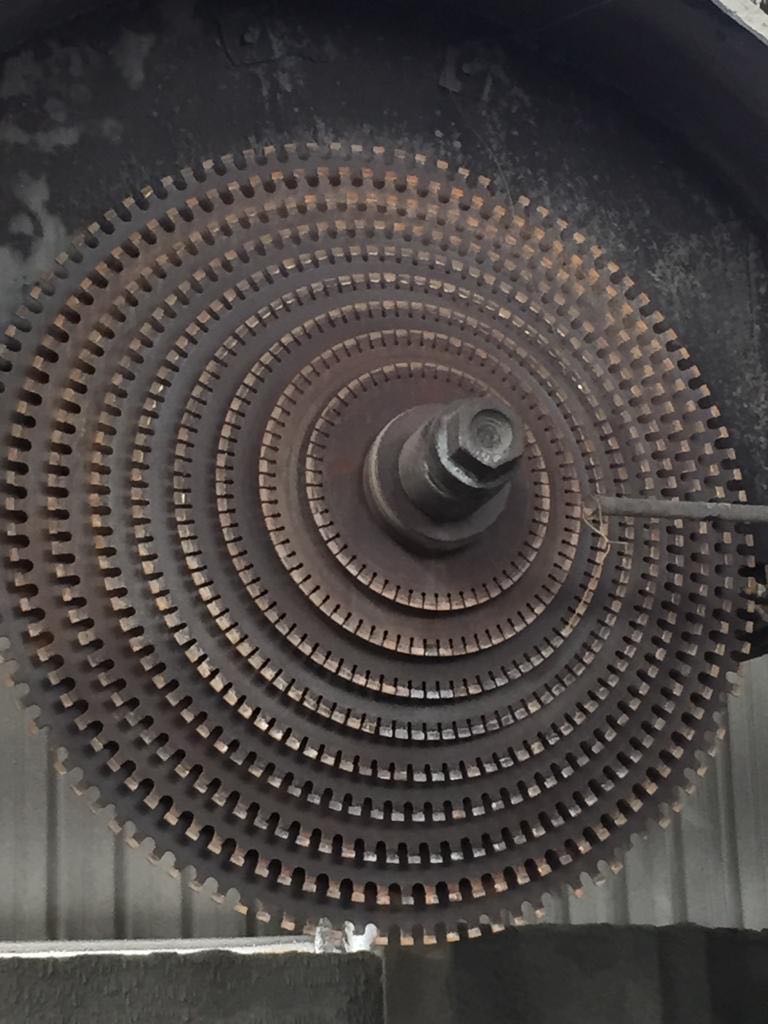

| STANDARD PROPERTIES – VERTICAL DISCS | |||

Diameter (mm) | Granite Thickness (mm) | Wide tooth (L) No. of Segments | Granite Segment Dimensions Length x Width x Height (mm) |

450 | 5.0-5.5- 6.0-6.5-7.0 | 52 | 24 x( saw+1mm) x 12.5 – 14.5 |

600 | 5.0-5.5- 6.0-6.5-7.0 | 72 | 24 x( saw+1mm) x 12.5 – 14.5 |

750 | 5.0-5.5- 6.0-6.5-7.0 | 80 | 24 x( saw+1mm) x 12.5 – 14.5 |

900 | 5.0-5.5- 6.0-6.5-7.0 | 88 | 24 x( saw+1mm) x 12.5 – 14.5 |

1050 | 5.0-5.5- 6.0-6.5-7.0 | 92 | 24 x( saw+1mm) x 12.5 – 14.5 |

1200 | 5.0-5.5- 6.0-6.5-7.0 | 92 | 24 x( saw+1mm) x 12.5 – 14.5 |

1350 | 5.0-5.5- 6.0-6.5-7.0 | 96 | 24 x( saw+1mm) x 12.5 – 14.5 |

1500 | 5.0-5.5- 6.0-6.5-7.0 | 96 | 24 x( saw+1mm) x 12.5 – 14.5 |

1650 | 5.0-5.5- 6.0-6.5-7.0 | 108 | 24 x( saw+1mm) x 12.5 – 14.5 |

1800 | 5.0-5.5- 6.0-6.5-7.0 | 118 | 24 x( saw+1mm) x 12.5 – 14.5 |

1950 | 5.0-5.5- 6.0-6.5-7.0 | 126 | 24 x( saw+1mm) x 12.5 – 14.5 |

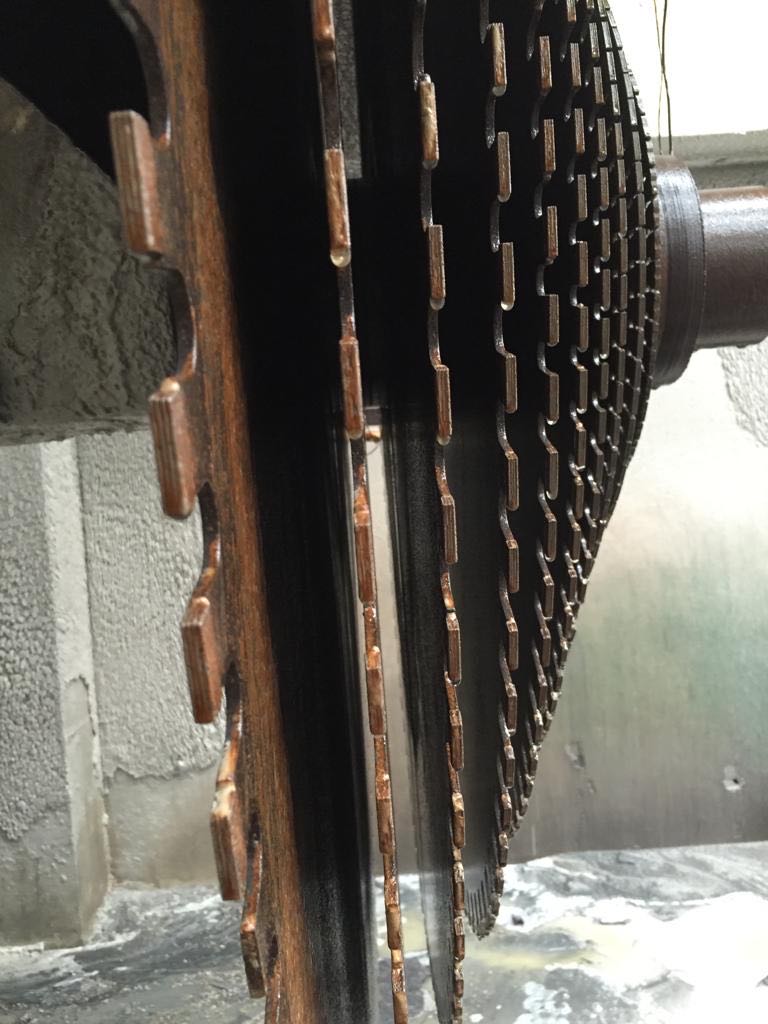

The disc for multi-disc block cutter is a diamond tool used on continuous machines with multiple diamond discs Chinese system is using multi diameter of blades to be hold on same shaft, all to be running same RPM ,,, this caused irregular wear out of segments,,, the small diameter saw blade segments will finish 2-3 times while the biggest diameter segment finish.

Through its in-house stone testing laboratory, ANADOLU DIAMOND can study the composition of the material to be worked on and offer the best performing diamond product suited to meet the customer’s needs. ANADOLU DIAMOND tools are designed and built with the most modern technologies and are for wet use only.

technical data that needs to be provided to identify the most suitable disc is:

Disc diameter- Bore- Narrow or wide slots- Type of material to be cut. Machine model and manufacturer